Interns Jump into Real-World Problem Solving

This summer, five interns joined the teams at Waudena and Diamond Kote, ready to learn and make a difference. Over two days, they dove into hands-on training that gave them a real taste of how Wausau Supply solves problems and improves processes every day.

Meet the Intern Team

- Sawyer Nitti – Engineering Intern, Waudena

- Calvin Clay – Engineering Intern, Diamond Kote

- Reid Scaife – Engineering Intern, Waudena

- Katie Schulz – Supply Chain Intern, Waudena

- Andrew Marsh – Engineering Co-op, Waudena

What They Learned

The interns started with a crash course in how we work smarter, not harder. They learned:

- How to spot waste in a process and focus on what really adds value.

- The 5S method for keeping workspaces clean, organized, and efficient.

- How to think in terms of processes, not just tasks.

- How to write clear work instructions that anyone can follow.

- The 7 Quality Tools—simple but powerful ways to collect and understand data so we can fix problems at the root.

These tools include things like charts, diagrams, and checklists that help teams see what’s really going on in a process.

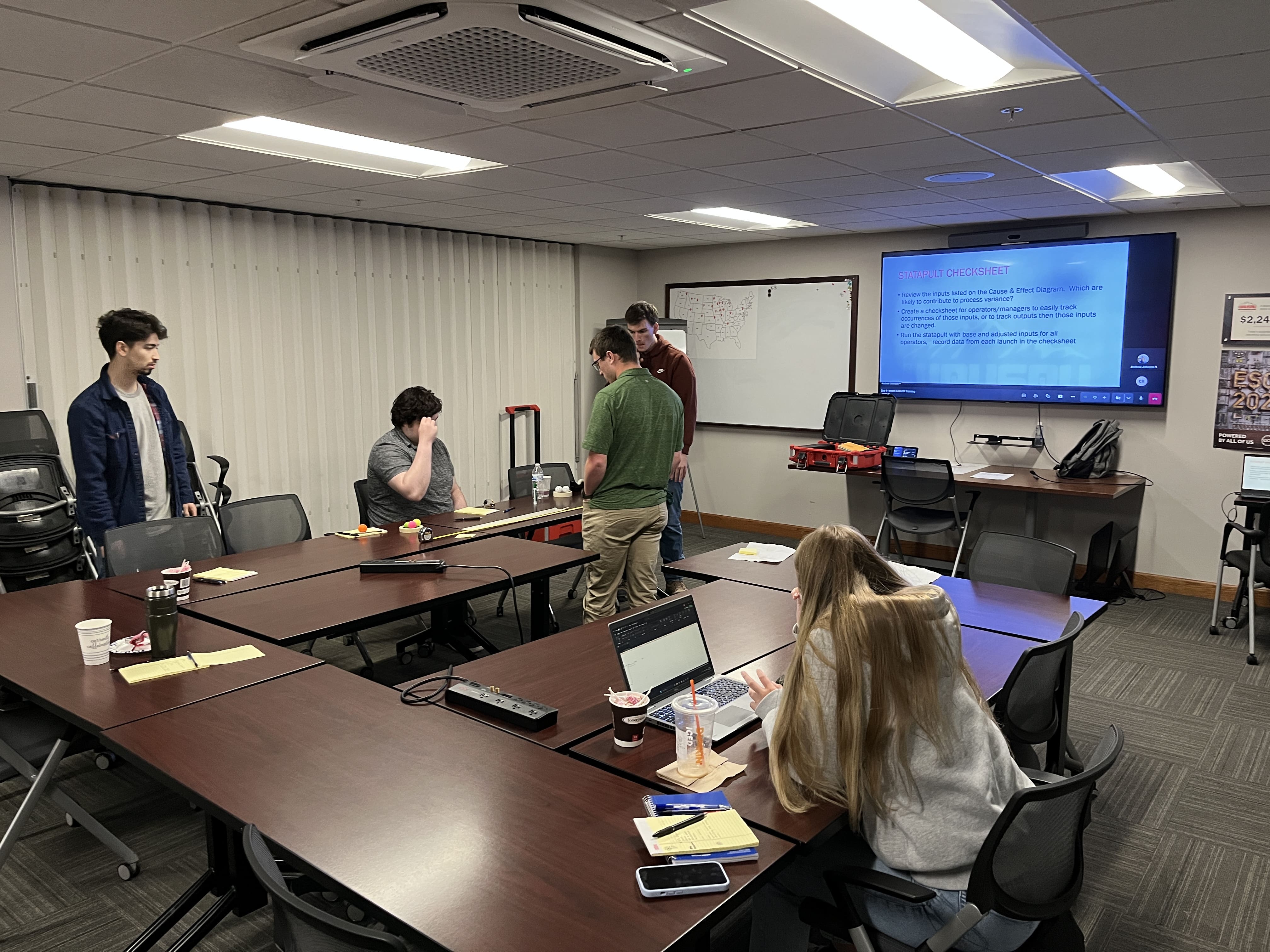

Putting it into Practice: The Statapult Challenge

The highlight of the training was a fun, hands-on activity using a tool called the Statapult—a device that launches small balls. The challenge? Make the balls land at a specific distance, just like a customer would request.

The interns worked together to:

- Write instructions for how to use the Statapult

- Use their new tools to figure out what affected the results

- Collect and analyze data

- Adjust the process to make it more accurate and consistent

It was a great way to turn theory into action—and have a little fun while doing it!

Learning the WSC Way

The interns also got a look at how Waudena and Diamond Kote approach continuous improvement, step by step:

- Start with leadership and choose the right projects

- Gather data to understand the current situation

- Analyze and improve the process

- Put changes into action and document them

- Share results and follow up to make sure improvements stick

Why it Matters

This training wasn’t just about learning new skills, it was about showing our interns how they can make a real impact. By the end of the two days, they weren’t just students, they were problem solvers.

We’re proud of the energy and curiosity these interns brought to the table, and we can’t wait to see what they do next!